Disclaimer

We may earn a commission when you use one of our coupons/links to make a purchase at no extra cost to you. Please support the site by using the links.

At this stage, I did not know what I want to do. I was really keen on fitting a turbo on this setup as well. The only problem was the cost. This project quickly became a very expensive project. I just closed my eye and decided, I want to do this.

Firstly I had to find out what I needed for this upgrade to the project and where to get it. I spoke to one of my contacts and he said he stocks a cast turbo exhaust manifold. He Also stocks some turbos but I would have to come to his shop to have a look at them. I was like a child at Christmas waiting to open up his presents. Of course, I shot through to his shop as quickly as I could.

First things first, I had a look at the exhaust manifold. It looked like good quality so that was a no brainer. Next up was the turbo. My contact asked me what I was planning to do. I explained the system I want to run to him.

What turbo to use?

My contact told me he had the perfect turbo for me. The turbo would complement the supercharger really well. It was a turbo capable of 450 kW. The problem with turbos like these they have a lot of lag. As I was going to run a supercharger with this turbo, well it was fine.

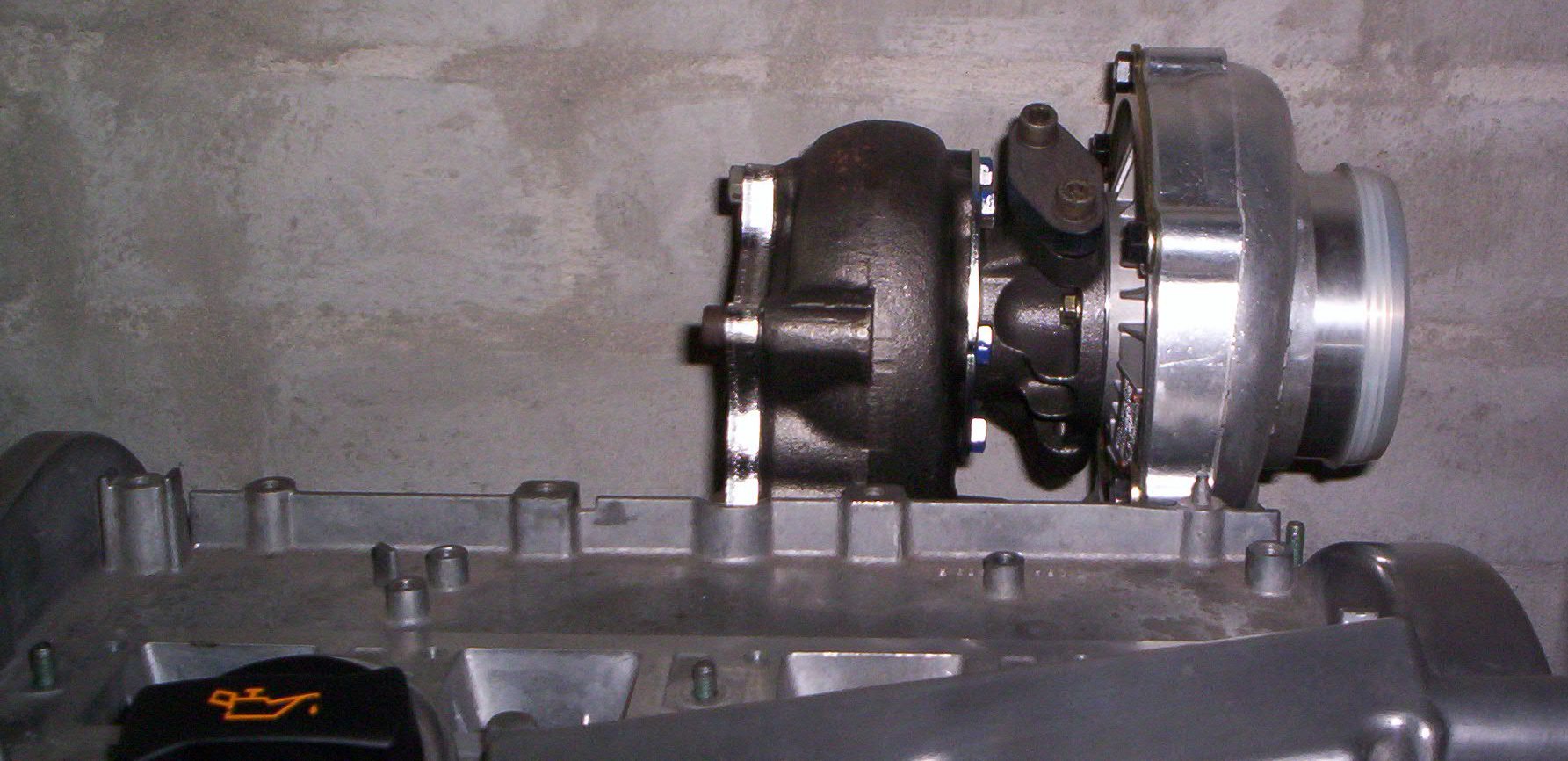

This was one huge turbo. It was a T3/T4 Hybrid turbo with a Volvo billet compressor wheel. From what I heard the Volvo billet compressor wheel was the best to use. The Turbo had an A/R 70 Compressor housing and a 0.63 turbine housing. This turbo did not have an internal wastegate so I had to buy an external wastegate. The Cast manifold had a mounting position underneath the casting for a wastegate. I had 2 more items on my list to get. One was a dump valve and the other was a set of injectors.

What injectors to get?

I got as set off 550cc Delphi injectors, this was the perfect size for what I was planning to do with the engine. The aim was to get as much power out of the motor but still using pump fuel. Now that I had most of the engine components I could do a dummy assembly of all the proper components.

Making a new Plenum…

One thing that I almost forgot about was that I needed a plenum for this motor. I designed a set of adapter flanges that could bolt onto the throttle bodies. The other side of the adapter flanges needed to be machined to a snug fit on a 63-millimeter aluminum tube. The one side of the tube needed to be machined like a hose tail and the other side would get a flange for the electronic throttle. Underneath the plenum, a boss was welded for the air temp sensor.

The inside of the plenum I sanded the joint with 80 grid emery paper to get a bell mouth, almost like a ram tube.

Doing the first proper test fit.

The next available weekend I clear my workbench at home. I wanted to do an assembly an make sure everything fits. I don’t want to get to the point that I start to build everything into the car and something doesn’t fit. Everything went together really well.

This engine looked like a piece of art, standing on the table. I almost didn’t want to put it in the car. Although this looks complete, there was some more thing to do before I could fit this into the polo.

One thought on “Must I throw a turbo in the works as well?”

Comments are closed.