Disclaimer

We may earn a commission when you use one of our coupons/links to make a purchase at no extra cost to you. Please support the site by using the links.

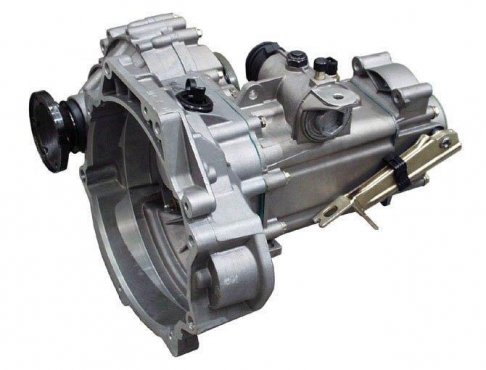

At this stage, I had most of the crucial parts of the build. There was one thing that was bothering me though. The gearbox that I was using in the polo was still the original rod select gearbox. I have been punishing this gearbox quite a bit. I started doing some research around what the weakest point is in the gearbox and how to fix it.

With heavy power engines on these gearboxes, the first thing that usually let go is the standard diff. The spider gears in the inside of the diff are just not strong enough and when they break they grenade the gearbox.

If the diff in your gearbox goes it usually means you need a new gearbox or at least new casing for the box. The spider gears hit holes into whatever material it can find.

So how do you fix it?

Well, the best thing to do is to fit a limited-slip diff. There are a few aftermarket diffs available for these gearboxes. I had a friend that had a genuine Volkswagen Motorsport LS 1.5 diff for these gearboxes. Like usually he didn’t want to get rid of the diff but after some persuasion, he sold it to me. The diff was a bit in the expensive side but it came with the upgraded stud kit for the crown wheel.

So what makes this diff so special? This is an LS 1.5 diff. You get different variants of LS diffs. There is an LS 1, which like the LS 1.5 has clutch plates inside that have a preload on them. When you turn your car and one wheel starts to turn faster than the other due to turning circle, the clutch will start to slip. This is only when load overcomes the springs in the diff. With the LS 1.5, it has a nice extra feature to it. It has a ramp and pin setup, so when you accelerate hard the pin wedges into the V ramp. This locks up the diff and there is no slippage. This means the power goes to both wheels equally.

Gearbox build.

It was December now and almost time for the company I worked for to close for the year. It was about 2 weeks before the shutdown. I decided it was time to start with the build. The first thing I did was to remove the gearbox. I took it to a friend of mine that agreed to rebuild my gearbox. While the gearbox is open he would do some gear changes as well. As this was a 2-liter engine he was going to change the 4th ad 5th gear to suite other 2 liter gearboxes. This would help to get even better fuel economy as the revs at high way traveling speed would be lower.

The biggest job on the gearbox rebuild was to get the crown wheel off the standard diff. The factory-fit the crown wheel with big steel rivets. These rivets are also one of the weak points of the gearboxes. The rivets had to get drilled out. This is a lengthy process as the rivets are very hard. As I got a replacement stud kit with my limited-slip diff I didn’t need to go buy a stud kit.

It was about a week later and I got the gearbox back. Now the gearbox was ready to accept the new power plant. I could now start to fit the engine and gearbox into the Polo.