Disclaimer

We may earn a commission when you use one of our coupons/links to make a purchase at no extra cost to you. Please support the site by using the links.

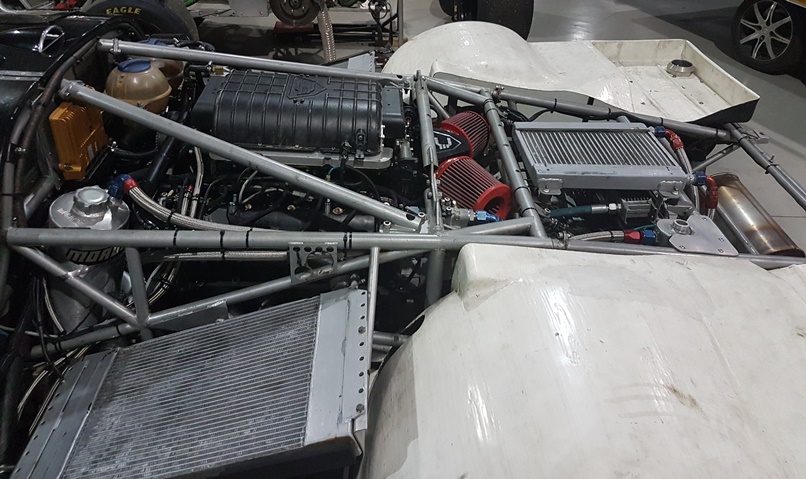

I just started back at the company after working at another company for 3 years. Mike was so glad to have me back and he was more into racing than ever. The Porsche 917 has been out for a few races after the upgrade to 700 Hp. The car was very problematic. It hasn’t finished one race. The car kept breaking down. If it wasn’t the one issue it was the next.

One of the issues the car had it kept on shredding the supercharger belt. It was so bad that the belt won’t survive one race weekend. Mike entered another race but this time I was going as well. I just needed to see what is going on with the car. Testing the car at work and testing the car at the track is completely different.

Race weekend

So we got to the race track the Friday. We were just in time for the afternoon practice session. The car was running well and there seemed to be no issues. Later the car went out again for qualifying and the car came in again. When getting to the garage Mike said that the oil light comes on when the revs go to low and then go off again as the revs pick up again.

This didn’t sound too good. I checked everything I could check and everything was fine. I added a bit of oil to the dry-sump system and the car was ready to go out again.

The next day arrived and we were all set and ready to go. It was race time and the Porsche went out. The car did a few laps and then we saw the yellow flag go out. We wondered what was going on. The green flag went out again and the race continued. The issues were the Porsche wasn’t between the car on the track.

The race ended and the Porsche was towed to the pit garage. The oil light came on during the race and the car lost power. We loaded the car and took it back to the workshop.

Inspecting the car

Back at work, we started looking at what the issue could be. It turned out that the standard adapter that sits on the crank that turns the OEM oil pump broke and the pulleys stop turning, This stopped all the pulleys turning. The oil pump, supercharger, and alternator all lost drive. That is why the dash lit up like a Christmas tree.

As a piece of the adapter had broken out that was still inside the engine. The engine had to come out. We had to inspect the engine to see if everything is ok and then get the broken piece of adapter out the crankcase. Upon stripping I found that there was to much free play between the supercharger lobs and the drive pulley of the supercharger as well. There was a plastic drive disc in the nose of the supercharger that was completely disintegrated. This was because the supercharger did not have a bypass valve. The breakage of the crank adapter was also because the wasn’t a bypass valve on the supercharger. The load on everything was just way too high.

With the 50 mm tooth belt we were running there was no forgiveness in the system and the crank adapter and drive disc in the supercharger was seeing all the loading when coming off throttle.

Oil pressure issue

I also decided to take the Moroso oil pump apart and see what the condition of the pump is looking like. I found 2 issues with the pump, there was a seal between the pressure side and the scavenge side that was damaged.

The other problem I found was the pump was badly worn. There was about 0.15mm clearance between the sides of the rotors and the housing. The clearance should be 0.05mm, if it is more than that then you will lose oil pressure. When the oil is cold and thick the pressure will be fine but as soon as the oil is on temp the pressure will drop out of spec. This is exactly what we were seeing.

Starting with the fixes…

My first priority was to get the Moroso pump up and working again. I ordered the new seal with spares from Moroso as I could only get the seals from them. I got the machine shop to machine the pump housings to get the surface true for the rotors to run against. Next, I made a steel disc the diameter of the pump housing and got is surface ground to a flat surface. I used this disc with fine valve lapping paste to lap the housing surfaces. After that I used some Autosol to get a smoother finish. This was very time consuming but this needed to be right.

I measured up all the stages and got the pump clearance on all the stages to be 0.05 mm. After washing everything I assembled the pump with the new seal. I through some oil down the ports of the pump and turned it over by hand. The pump had a nice and tight feel to it. The pump wasn’t sticking it just felt right.

Next up I designed a new adapter for the crank. As we were running an external dry-sump pump we didn’t need all the detail on the adapter. The adapter was now going to be a steel billet part instead of a cast steel part.

Fixing the belt issues

After some investigation, I found a issue with the steel supercharger pulley. The pulley didn’t machine very well due to the fact that the steel is very hard and a small cutter had to be used to cut the pulley. I check this on a previous pulley setup we had on the shelf that we used for the development of the engine. The belt did not naturally sit nicely in the grooves. The belt had to be stretched into the grooves.

I ended up redoing the profile and added in some more clearance so that we could re-machine the profile so that the belt could sit properly in the groove by itself. Having to have had pulled the belt into the profile will cause excessive wear on the belt and cause it to prematurely fail.

Now for some updated

As we had issues with stuff breaking due to not having a bypass valve on the supercharger I made a plan. We just needed one and I was not going to take no for a answer. I designed the parts needed and ordered everything. Some of the parts we could make in our own machine shop.

It was round about this time as well that my boss designed a now intake housing for the Supercharger as the one on there was restricting the airflow into the charger. I adapted his design to take the bypass valve. The setup worked out very nicely.

I decided that while everything was open now that I would do some extra mods, this is a race car so every bit counts. I had a look at the charger cooler setup on the engine. This how it was designed for production engines. It had to be an easy machining operation.

I got the machine shop to machine round on all the edges so that there is no turbulence over the sharp edges. After that, I polished the casing around the aria was it was machined to have a nice and smooth transition area.

I also checked out the height between the cooler cartridge and the base plate, I found that the cooler was running to close to the base plate. At higher airflow, this could cause a restriction. So I made a spacer flange to lift the cooler up by 10 mm. This would give more than enough area for the air to flow through.

Air filters

There was another thing I noticed. The guys were running 2 K&N filters one on each of the throttles. They were not looking that good. It almost looked like the filters were sucked in. I calculated the volume of air this charger pumped at 7000 RPM. What I found was that the 2 filters could not cope with 41250 liters of air per minute. The filter was choking the engine. When we ran the engine on the dyno we didn’t have any filters on the engine as it was a clean environment.

I found 2 big cone filters from BMC that would do the job. All I had to do was to make a box that would connect on the 2 throttles and the 2 throttles will share the 2 filters. Space was my biggest issue but everything worked out well.

Now that all the issues were addressed the engine could go back into the car.

Ready to race

The engine went back in and everything connected back up. On startup, the oil pressure was nice and high and as soon as the engine got to temp the pressure still remained high. I was happy, the engine sounded healthy. We were once again ready to go race.

At the next event the Porsche 917 went out for qualifying, the car ran really well.

The car ran really well the whole weekend. The Porsche finished a race for the first time since the new motor went in. When Mike got back to the pit garage with the car, he said that he had to through some water in the cooling system when he came off the track. The coolant gauge was showing 130 deg C. We opened up the back end of the car and the one radiator was blown up like a balloon. The one-tube had a hole in it. The car ran a bit hot and build up to much pressure and blew the radiator. Well, at least we finished the race. We could not expect the cooling system to cope with all the extra power.

The Porsche 917 went back to the workshop so we could see what we could do to make it cope with the extra power.

3 thoughts on “What a mess!”

Nice blog here! Also your website loads up very fast! What web host are you using? Can I get your affiliate link to your host? I wish my web site loaded up as quickly as yours lol

Hi, Here is a link you can use: https://www.bluehost.com/track/chcrasyideas/

Comments are closed.