Disclaimer

We may earn a commission when you use one of our coupons/links to make a purchase at no extra cost to you. Please support the site by using the links.

Now that we have the engine it is time to sort out all the other parts of the car. It is like a child at Christmas with all the toys around the tree. This is going to be one serious build so all the best parts have to go into it.

What gearbox to use?

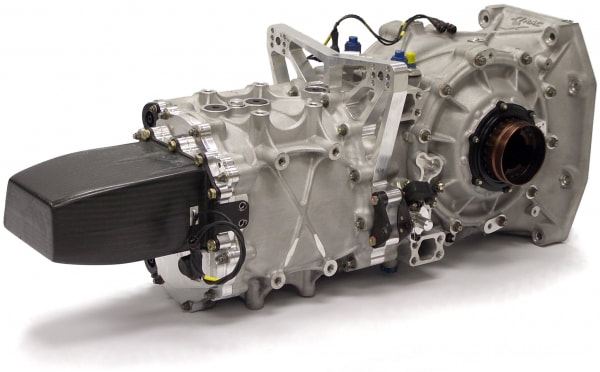

As the supercharged VK45 engine puts out 560Hp and 635Nm torque we would need s serious gearbox on here. Like I have said in my previous posts, enough is never enough. Once you get used to power you always want more. My boss decided that he wanted a proper sequential gearbox in the car. He contacted his friend at Xtrac in the UK for a gearbox. He recommended the Xtrac 396 6 speed sequential gearbox they make. The gearbox can handle up to 1500 Nm on its input shaft. The box is on the pricey side but it is a proven box that has been trailed and tested over many years.

All we needed to do was to design a bell housing that will mate this gearbox to the VK45DE. We took one of the bell housings that we used on our boat projects and machined the one side off to make a place for the new mating flange for the gearbox. We welded a piece of aluminium plate to the machined bell housing. After that, we set up the bell housing on the vertical Haas CNC Mill and we machined the flange true to the bell housing casting.

This bell housing looked like a piece of art. We were in the position to be able to bolt the gearbox and engine together so we could see what our package size is going to be.

What clutch will we use?

We wanted to use one of the biggest brands in racing clutches as we knew they were the best. We ordered a 184 millimetre sintered 3 plate AP Racing clutch with an AP Racing concentric slave cylinder.

The pressure plate we ordered with the clutch kit was the highest clamp force for this size clutch. The clutch could handle up to 1500 Nm of torque. Because of the small diameter of the clutch, we could design a small diameter flywheel which would make the car very easy revving. We were fitting some serious toys in this car.

Shifting?

Xtrac sent the gearbox to Pro-Shift to get an electrically actuated shifter kit installed on the gearbox. They ran the gearbox on their gearbox dyno to set up the controller. This would make the shifting allot easier on this car.

The Pro-Shift controller would be able to do ignition cat and throttle blip, so the car would be able to full-power gear shift without using the clutch.

We had the heart of the car all we needed the body!